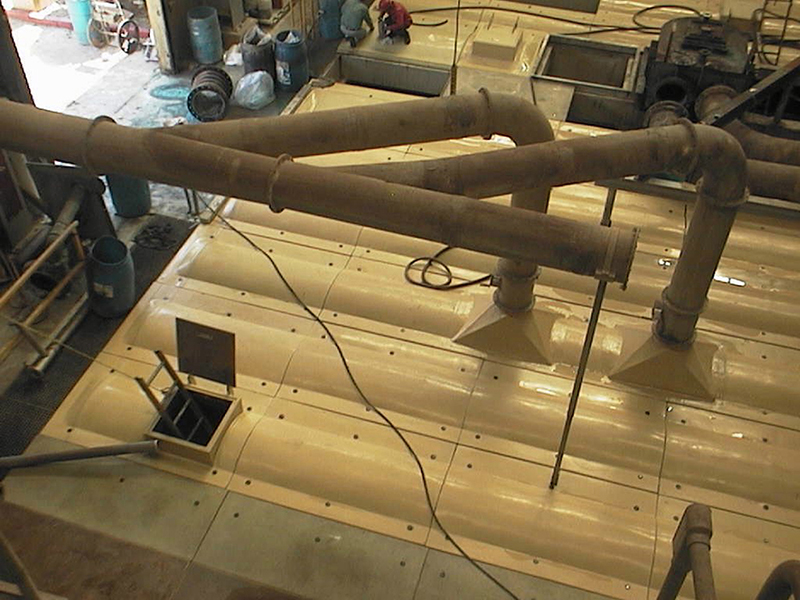

Domes and roofs

• Description: They are architectural elements that are commonly used to cover up large areas, allowing a better use of space in the interior. They can be used in common areas and also in the chemical industry to cover spaces and/or large equipment, for which a rectangular dome or a set of consecutive flat coverings will have the function of covering equipment which emanates a quantity of undesirable gases or to cover an area in an external saline environment where the best option in order to prevent corrosion is fiberglass.

• Design ranges: for the construction of a dome or covering, space is not a limiting factor, Lapsolite offers a wide range of domes and coverings of the following types:

- Type IA: Covers formed by elements of a certain width and height where lengths are variable, but retaining the same type of elements, to cover areas up to 58,000 m2, appropriate for activated sludge pits.

- Type IB: Coverings formed by elements of a certain width and height to cover variable lengths, recommended for covering gutters up to 120 m in length.

- Type II: Semi-elliptical coverings which are self-supported, conformed by elements of a specified height and width to cover very extensive areas, suitable for activator tanks.

- Type III: Coverings for booths or cabins which can be used in filter press compartments with dimensions of 17 x 11 x 4 meters.

- Type IV: Flat type coverings of geometric shapes used as reinforcements to cover reactors or circular tanks, ideal for multi-purpose containers and sludge storage tanks and can cover diameters of up to 16.5 m.

- Type V: dome-type covers ideal for mixing tanks, trickle-filter type tanks, sludge storage tanks and can cover diameters of up to 50 m.

- Type VI: Covers that combine the alternative of manufacture of domes with separate elements or flat tops over cylindrical pits where there is a need to design options for operation and maintenance as in pits for pre-clarification, sludge storage tanks, able to cover diameters of up to 60 m.

- Type VII: Covers that combine all the previous settings and that are used for post-thickener tanks, which require external elements such as metal structures appropriate for the operation of the agitators and mixers and can cover diameters of up to 40 m.

- Type VIII: Covers suitable and recommended for pumping stations, which are a variant of type I.

In the industry domes constructed from resin reinforced with fiberglass are generally used to cover biological reactors since it is necessary to use a material that is resistant to the acid vapors released during the reactions that occur in the interior of the equipment. For more information please contact our Engineering Department.

• Applications: Industrial plants (metallurgical, chemical, petrochemical, pharmaceutical, etc.) shopping centers, hospitals, bus terminals.

• Benefits:

a. Light-weight compared to traditional construction of coverings or lids.

b. Don’t require supportive structure, as they are self-supporting.

c. High chemical resistance when using reinforced or thermoplastic resins.

d. Greater use of space.

ENGLISH

ENGLISH